To answer the question “what is Ergonomics” we will start with a dictionary definition of it.

Ergonomics is defined by most dictionaries as:

- The applied science of equipment design, as for the workplace, intended to maximize productivity by reducing operator fatigue and discomfort. Also called biotechnology, human engineering, human factors engineering.

- Design factors, as for the workplace, intended to maximize productivity by minimizing operator fatigue and discomfort:

Let us now give you a better more functional definition, we use:

Ergonomics is the use of our understanding of the human body’s limitations and weaknesses, applied to the design and layout of workplace and procedures, to minimize the negative effects on workers, allowing them to perform at their maximum level throughout their shift.

Ergonomics is so important and in fact the basics are so understandable that everyone should know about it. Poor Ergonomic layout has resulted in dramatic increase in worker injuries, as well as seriously hampered both quality and productivity. Applying good ergonomics to the workplace and work procedures will benefit both employers and employees.

A basic understanding of ergonomics will result in lower costs for employers, as well as helping to raise productivity. Let us look at some of the cost and how it will reduce them.

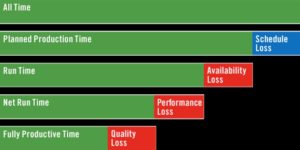

In any discussion with business owners two topics always come up, the high cost of healthcare and workers compensation. These two are highly related costs in fact. First of all we have to understand and be willing to accept the facts. In every study of worker injuries it has been shown that most injuries occur during the later portions of work shifts. This is simple to understand why people are far more tried at the end of the shift than at the beginning, with physical fatigue comes mental fatigue. When anyone is mentally tried their natural defence mechanisms are slower to react, hence they are far more likely to have an accident. It is this accepted fact that has resulted in the strict limitations on work hours placed upon pilots, and professional drives fatigue creates dangerous situations. With every injury and through constant exhaustion health cost increase, simply because employees are wearing out their bodies.

Even if workers do not get personally injured there are still other costs that increase due to worker fatigue. Defect rates increase as does scrap during the later part of shifts. As workers become fatigue their ability to perform declines, thus productivity levels are lower at the end of a shift when worker fatigue is common.

Good Ergonomic design will help reduce these costs, and will allow your employees to perform at their best for their entire shift. It is critical to remember that lower cost and improved productivity will both positively affect your competitive position and your bottom line.