Now we turn to Standardized Work a term that is often confused with another commonly used term Work Standards. Firstly both supposedly serve the same purpose, that being creating one way of doing a job; however they do it in very different ways. That difference is the reason why Standardized Work drives improvement while Work Standards only deliver stagnation and mediocrity.

Before answer the question “What is Standardized Work” it will be helpful to first understand “What Work Standards Are” so we will start by discussing them.

Work Standards

Work Standards came into existence during the 1900’s as management practise shifted first to Taylorist and then Neo-Taylorist scientific management ideas. Although Taylor never started with the premise that workers were simply mindless individuals that need to be totally controlled he did to start place greater emphasis on managers’ ideas and on management controls than anyone else had ever done. By the time scientific management became solidly in bedded in many major enterprises Work Standards had become the tool used to control the work force.

A Work Standard is a management driven way of controlling the work of the workers. Experts decide in advance how a job should be done, how long it should take, and how problems are to be handled. Under this system a worker is treated as nothing more than another piece of equipment. Thus all the worker has to do is act like a mindless robot, and simply do exactly as they have been instructed. The worker is not to care about quality, improvement, productivity, downtime or anything else, they simply do what they have been assigned and nothing else.

This was exactly the same way that communist factories of Russia ran if a part or ingredient was missing they simply ignored it and continued doing their job. That is how they meet production numbers assigned to them, after all it did not matter if the product produced worked or not, it was produced. Unfortunately that way of doing things is not that different from how we in the Western world often ran our businesses.

The artificial standards created, do not encourage anyone to improve a system, instead they discourage it. Work Standards are just one of the many ways in which scientific management drove a wedge between workers, managers, owners, suppliers, customers, and consumers.

Standardized Work

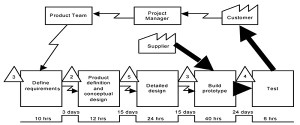

What is Standardized Work? Standardized Work is a work control system that is designed and improved by those doing the work. Under Standard Work workers first determine; what is the best way to do a job, how long each part of a job takes, and then they constantly consider and test ideas to improve it. After they have done this they either write out or diagram the standard work instructions, or they work with engineers or managers who aid in writing them out. The purpose of them is so that even a new worker can achieve the desired results quickly.

Today the creation of Standardized Work is often credited to Toyota, however it is in reality not new nor Toyota`s idea. It has its basis back in the days of craftsmanship, when most products were in fact produced by skilled workers. Talented skilled workers devised and improve their craft and passed their knowledge on to those they trained. If you look at the practises and improvements in any trade you will see that overtime each generation of craftsman improved their craft over the previous generation.

The industrial revolution was driven by people working together to find better ways of doing everything. If you look, at many of the creators and leaders of that era, they worked with workers to find ways to improve production.

During the Second World War, the US governments TWI agency, used the basic ideas of standardized work to help drive the industrial production levels to those required to win the war effort. TWI taught managers how to work with their employees to constantly find better ways of doing their jobs so they could produce just a little more. Immediately after the war most of our enterprises went back to our old ways, and devastated Japanese started to apply the knowledge of TWI to help them rebuild their economy. To their credit Japanese companies such as Toyota were smart enough and humble enough to learn and accept the fact that Standardizing work is a job for the work force that should be supported by management and engineering.

Standardized Work is like everything else in Lean it is a never ending journey, not a destination. Today’s best method of doing something is outdated tomorrow, only by using the talent and ideas of everyone can an organization manage to constantly improve, adapt and grow. Waiting for experts to first realize there is a problem, then devise a solution, and finally manage to implement; is just to slow a process in today’s high speed economy. Additionally while you are waiting for the experts to implement their solution an agile competitor who relies on his whole organization to drive improvement will have not only dealt with that problem, but many others as well.

Conclusion

We hope this has answered your question “What is Standardized Work” for you. Additionally we hope that you understand that Standardized Work is not about creating a permanent Standard, rather that it is simply a way of ensuring that works is done in a standardized or uniform way until you can find a better way to do it.