What is Total Productive Maintenance

There are two common questions asked often “What is TPM or What is Total Productive Maintenance” and two “how is TPM different from Preventive Maintenance”, on this page we will answer both question for you. We will start by answering the second question first on this page.

How is TPM Different From Preventative Maintenance

TPM is not a replacement for Preventative Maintenance rather TPM covers Preventative Maintenance and than does much more to keep your Equipment running, it adds something called autonomous maintenance. The easiest way to grasp this is if I give you a simple example as an illustration.

One of our owners grew up on a farm, and he came up with this simple explanation based on what good farmers do to ensure their equipment is operational during their most vital seasons.

“On the farm we always had what would today be called a TPM program, even if it was never referred to as such. It always started with Preventative Maintenance that was planned and performed at times when the equipment was not vitally important.

For example let use a tractor What is Preventative Maintenance for it:

- every 10 years get engine rebuilt in the winter

- every five years get brakes redone, and the hydraulic fluids and filters replaced

- twice a year oil and fuel filters are replaced, the oil is changed, and then every grease nipple is checked to see it still works

- check various bearings and other parts for wear to see if they needed replacement

A tractor Autonomous Maintenance program performed by every tractor driver daily:

- check the oil before starting at tractor in the morning and after each refuelling stop

- every fitting greased everyday in the morning

- tires were checked daily

- pins were checked every time you checked the oil

- hydraulic lines checked every evening for leaks

- fill the fuel tank every morning day and often refuel them at lunch and supper breaks

- monitored the fuel gauge regularly

- air filters were checked and cleaned at every stop, or an oil bath air filter cleaned every other day

- clean mud and dirt off tractor daily

So you see a farmer and mechanics all perform certain basic Preventative Maintenance jobs, and then the driver (operator) does his regularly daily maintenance, both of which are necessary to not losing a hour of valuable planting or harvesting time, just to ensure the maximum yield and quality.”

Now let us tie this to a factory, in a factory maintenance may change bearings every so many production hours, rebuild electric motors etc. that is all preventative maintenance and part of TPM. But TPM adds to that the operator, who helps keep machines running, by checking fluid levels, greasing fittings, cleaning the machine (remove chips, grindings, filling, etc.), checking for lose bolts and pins, and just monitoring it for signs it is acting up. It often shocks people that a few minutes of simple maintenance, will not only reduce repair costs, but often dramatically improves productivity.

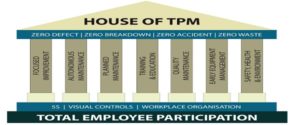

What is TPM

Total Productive Maintenance is the addition of Autonomous Maintenance (operator maintenance) to a solid Preventative Maintenance program performed by your maintenance department. Operators help by first ensure all regular cleaning and lubrication gets done, they check for problems before a breakdown causes more damage to a machine, and they monitor and report how there machine is performing so maintenance can repair it before it breaks and at a time when you can have it shut down.

The goal of a TPM program is to ensure that your equipment can produce for all of its schedule production time. It works to minimize and eliminate downtime, which drives repair cost, increase defects and scrap costs, lower quality, increase production cost as overtime is need to make up production. It can often be found that a good autonomous maintenance program will gain you back more actual minutes of production from downtime than it takes to perform, if it doesn’t than something is wrong.