“If you can not measure it, you can not improve it.”(Lord Kelvin)

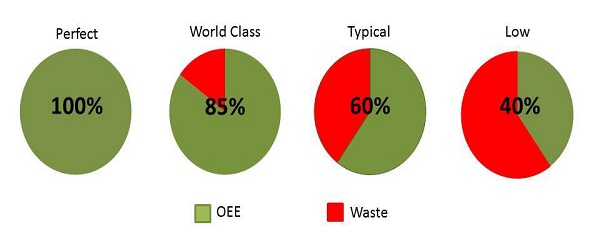

It is a common opinion that productivity improvement is nowadays the biggest challenge for companies in order to remain competitive in a global market. A well-known way of measuring the effectiveness is the Overall Equipment Efficiency (OEE) index. It has been firstly developed by the Japan Institute for Plant Maintenance (JIPM) and it is widely used in many industries. Moreover it is the backbone of methodologies for quality improvement as TQM and Lean Production.

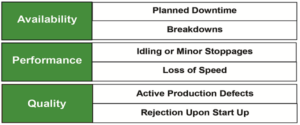

The strength of the OEE index is in making losses more transparent and in highlighting areas of improvement.

OEE is often seen as a catalyst for change and it is easy to understand as a lot of articles and discussion have been generated about this topic over the last years.

The aim of this chapter is to answer to general questions as what to measure? how to measure? andhow to use the measurements? in order to optimize the factory performance. The goal is to show as OEE is a good base for optimizing the factory performance. Moreover OEE’s evolutions are the perfect response even in advanced frameworks.

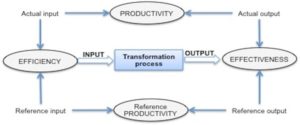

This chapter begins with an explanation of the difference between efficiency, effectiveness and productivity as well as with a formal definition for the components of effectiveness. Mathematical formulas for calculating OEE are provided too.

After the introduction to the fundamental of OEE, some interesting issues concerning the way to implement the index are investigated. Starting with the question that in calculating OEE you have to take into consideration machines as operating in a linked and complex environment.

So we analyze almost a model for the OEE calculation that lets a wider approach to the performance of the whole factory. The second issue concerns with monitoring the factory performance through OEE. It implies that information for decision-making have to be guaranteed real-time. It is possible only through automated systems for calculating OEE and through the capability to collect a large amount of data.

So we propose an examination of the main automated OEE systems from the simplest to high-level systems integrated into ERP software. Even data collection strategies are screened for rigorous measurement of OEE.

The last issue deals with how OEE has evolved into tools like TEEP, PEE, OFE, OPE and OAE in order to fit with different requirements.

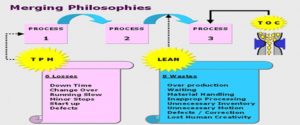

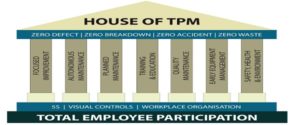

Overall equipment efficiency or effectiveness (OEE) is a hierarchy of metrics proposed by Seiichi Nakajima to measure the performance of the equipment in a factory. OEE is a really powerful tool that can be used also to perform diagnostics as well as to compare production units in differing industries. The OEE has born as the backbone of Total Productive Maintenance (TPM) and then of other techniques employed in asset management programs, Lean manufacturing, Six Sigma, World Class Manufacturing.

By the end of the 1980’s, the concept of Total Production Maintenance became more widely known in the Western world and along with it OEE implementation too. From then on an extensive literature made OEE accessible and feasible for many Western companies.