Intellectual Property : A Strategic Issue for Ventures

The ownership and protection of intellectual property is a strategic issue – particularly for high growth potential ventures in science and technology. It can also […]

The ownership and protection of intellectual property is a strategic issue – particularly for high growth potential ventures in science and technology. It can also […]

There are legal insurance requirements that must be in place for all businesses. We also review other areas we strongly advise you to obtain cover […]

Share Options Schemes for High Growth Potential Ventures In order to persuade quality management into the venture it is often necessary to offer the incentive […]

The legal aspects of employment are important when developing a venture that aims to attract investment and deliver an ambitious business plan. This outline highlights […]

The Financial Plan is a quantified vision of your project upon which much of your credibility with investors will rest – get it right and […]

The Business Plan articulates your project and is the fundamental tool for communicating with investors. A well produced business plan will give you an edge. […]

The executive summary is the most important part of the business plan. Many people will only read this. If it does not capture the attention […]

Innovation and Entrepreneurship are creative processes. They are usually born out of dissatisfaction with the current order. Here are a few words on the required […]

The Management Team is fundamentally important in any new venture. You need to show that the business has not only identified a viable opportunity but […]

You only get one chance to persuade each target that your project, of the hundreds they see, is worth staking their hard-earned, risk free, money […]

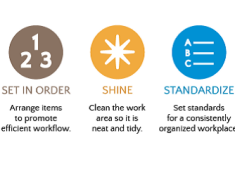

5S is a methodology for organization, standardization and cleanliness. At the heart of 5S is the lean goal of reducing waste. 5S addresses the wastes […]

The straighten step establishes designated locations for everything. This ensures that tools, materials and resources can be found easily when they are needed, and are […]

As with any program, success is dependent on the expectations, guidelines and continued monitoring of the program. 5S is not a spring cleaning activity that […]

The most important element of 5S is developing and encouraging total employee involvement. 5S is not a program for a portion of the workforce. Everyone, […]

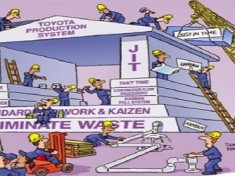

Lean Manufacturing provides a methodology for eliminating waste and improving organizations. This methodology developed over the last 50+ years, and has yielded a wide array […]

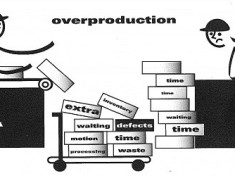

The 7 Wastes provide a central theme to the lean methodology. The goal of lean is to maximize value and minimize waste. Ultimately, value to […]

The Toyota Production System is the methodology developed at Toyota that led to the development of lean manufacturing and the lean philosophy. The Toyota Production […]

Poor quality and the resulting defects are a major source of cost for many companies. This is also a cost that is often under reported […]

Motion is a waste common in both manufacturing and service industries. This waste is very similar to transportation waste, but relates to movement within a […]

Processing activities are typically viewed as value added. It is the manufacturing processes that add value to the product and to the customer. Despite this, […]

Transportation is the backbone of our economy, but it is also a fundament waste to be eliminated. As important as it is to get a […]

Waiting is one of the 7 Wastes that most people recognize easily. Eliminating time spent waiting has been a focus of manufacturing improvement activities since […]

Inventory is recognized in as a waste in the lean system. This is because inventory does not add any value to the customer, but has […]

Overproduction occurs when a company manufacturers a product before there is a customer demand. Overproduction can occur with individual processes or across the entire value […]

In Lean Thinking and in Life in general we often like to write out neat little equations to explain complex concepts so that people understand […]

In this post we are going to suggest another Lean tool that may be beneficial for our children to learn Autonomous Maintenance (i.e. Operator Maintenance). Kids […]

Knowing When You’re Lean Recently I have been seeing more and more discussion about Lean Maturity and people asking us how they know they are […]

What is the best way of implementing Lean Manufacturing? What is that magic recipe that would guarantee us that, if we follow it, the Lean Transformation […]

Copyright © 2024 | WordPress Theme by MH Themes