Implementing 5S Workplace Organization Methodology

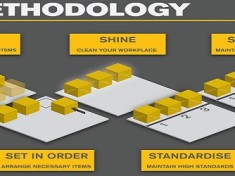

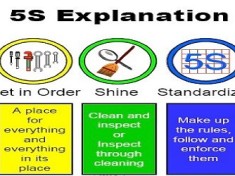

5S is a methodology for organization, standardization and cleanliness. At the heart of 5S is the lean goal of reducing waste. 5S addresses the wastes […]

5S is a methodology for organization, standardization and cleanliness. At the heart of 5S is the lean goal of reducing waste. 5S addresses the wastes […]

The straighten step establishes designated locations for everything. This ensures that tools, materials and resources can be found easily when they are needed, and are […]

As with any program, success is dependent on the expectations, guidelines and continued monitoring of the program. 5S is not a spring cleaning activity that […]

The most important element of 5S is developing and encouraging total employee involvement. 5S is not a program for a portion of the workforce. Everyone, […]

The 5S program highlights basic aspects such as using the proper tool, the proper accessory, and the correct information. It seeks respect for arranged times […]

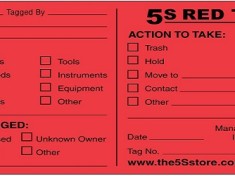

5S Red Tag procedures (Free download 5S red tag template below) Step 1: Select members from various teams Select a high level manager to participate […]

Abstract. Supply strategies in a lean environment should support the operations strategy. It is appropriate then to use lean concepts and lean terminology in the […]

When you begin to work at a place, you usually start at the bottom of the scale. You have to make your way to the […]

We will attempt to answer the common question “What is 5S really?” Let us start by defining 5S: 5S is a practise the results in […]

Copyright © 2024 | WordPress Theme by MH Themes