5S Red Tag procedures

(Free download 5S red tag template below)

Step 1: Select members from various teams

- Select a high level manager to participate as a team member

Step 2: Identify 5s Red Tag targets

- Inventory, equipment, supplies, tooling, space

- Office areas are not exempt from red tagging

Step 3: Define Red Tag criteria

- Determine what criteria will be used to distinguish a needed item from an unneeded item

- Example: Save only the items needed to conduct daily business in the area

Step 4: Explain red tag criteria to teams

- Ensure a good cross-section of people tagging items to prevent “I might need that”

- Red-tag work area as rapidly as possible

Step 5: Evaluate red tag items

- Review material which has been red tagged

- Dispose of truly unnecessary inventory, equipment and other items

- Teams may retain material which has been red tagged if they can show proper justification

- Discard any material which is still tagged after a pre-determined time

- All red tags must be completed and returned to red tag coordinator

Red Tagging Helpful Hints

- Record information about all tags used on a 5S Red Tag Log so that dispositioned items can be tracked easily.

- Make sure everybody understands what is to be red tagged and why.

- Discourage people from being defensive. Be fair – all areas get tagged!

- Don’t red tag people.

- Don’t compromise; IF IN DOUBT, THROW IT OUT!

- Necessary items can be tagged if improvements are known or suggested.

- Do not put multiple tags on any one object.

- Make reasonable allowances for decorative items such as family pictures, plants.

- Disposition all red tags

Red tag process

- Usually two different approaches;

- Team identifies and labels all unnecessary items over a one to two week period within working area

- Blitz approach; team uses red tags to only identify items that cannot be removed safely or easily. All other items scrapped or moved to

“crime watch area”.

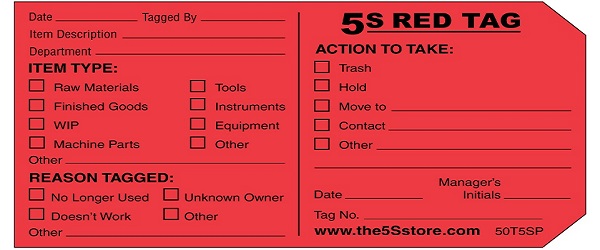

5S Red Tags – A Useful Sorting Tool

The red tag is a useful tool to help the sorting process – in the factory, warehouse, or office. These tags are used to identify unnecessary items that need to be either thrown out, recycled, sold or relocated. They are especially useful as a visual management tool as they easily communicate visually to other staff members that the tagged items are unneeded/unwanted.

Free Download 5S red tag template

Free 5S_Red_Tag_Excel template

5S presentation ppt slides