The 7 Wastes

The 7 Wastes provide a central theme to the lean methodology. The goal of lean is to maximize value and minimize waste. Ultimately, value to […]

The 7 Wastes provide a central theme to the lean methodology. The goal of lean is to maximize value and minimize waste. Ultimately, value to […]

The Toyota Production System is the methodology developed at Toyota that led to the development of lean manufacturing and the lean philosophy. The Toyota Production […]

Poor quality and the resulting defects are a major source of cost for many companies. This is also a cost that is often under reported […]

Motion is a waste common in both manufacturing and service industries. This waste is very similar to transportation waste, but relates to movement within a […]

Processing activities are typically viewed as value added. It is the manufacturing processes that add value to the product and to the customer. Despite this, […]

Transportation is the backbone of our economy, but it is also a fundament waste to be eliminated. As important as it is to get a […]

Waiting is one of the 7 Wastes that most people recognize easily. Eliminating time spent waiting has been a focus of manufacturing improvement activities since […]

Inventory is recognized in as a waste in the lean system. This is because inventory does not add any value to the customer, but has […]

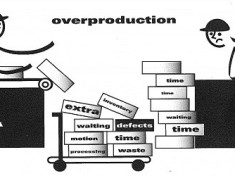

Overproduction occurs when a company manufacturers a product before there is a customer demand. Overproduction can occur with individual processes or across the entire value […]

In Lean Thinking and in Life in general we often like to write out neat little equations to explain complex concepts so that people understand […]

In this post we are going to suggest another Lean tool that may be beneficial for our children to learn Autonomous Maintenance (i.e. Operator Maintenance). Kids […]

Knowing When You’re Lean Recently I have been seeing more and more discussion about Lean Maturity and people asking us how they know they are […]

What is the best way of implementing Lean Manufacturing? What is that magic recipe that would guarantee us that, if we follow it, the Lean Transformation […]

A large part of being successful in a Lean Transformation is repect for people one way we show that is through becoming a more diverse […]

Why in Lean Implementation is it vital to build an organization based upon Respect for People? This simple and commonly asked question is the most […]

The question “What is the key to successful Lean Implementation?” is often asked of us. The answer is simply yet, the toughest part of Lean […]

The 5S program highlights basic aspects such as using the proper tool, the proper accessory, and the correct information. It seeks respect for arranged times […]

Prior to applying for online jobs, it is wise to delineate your area of expertise~If you are looking at online jobs, as with any other […]

In this is the first article in which we will touch on some of life’s lessons any of us over thirty should have learned by […]

Most Value Stream Mapping is done on totally manmade systems, which exist in hard goods factories, and service businesses, however there are several industries which […]

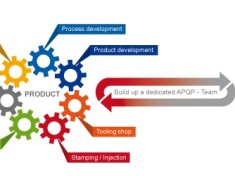

Purpose: To validate the manufacturing process through an evaluation of a production trial run. Considerations: During the production trial run, the APQP Team must validate […]

Background Fortune 1000 organizations have realized immense success by implementing the Define, Measure, Analyze, Improve, Control (DMAIC) methods made famous by Six Sigma practictioners. These […]

5S Red Tag procedures (Free download 5S red tag template below) Step 1: Select members from various teams Select a high level manager to participate […]

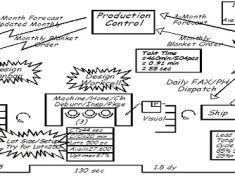

Step 1 – Determine Product Volume and Mix These categories represent marketing’s definition of product groupings and correspond roughly to divisions in the company’s product […]

1. Agree on scope and objectives. Know the details that this VSM for some product family, Top level / Middle level / Bottom level. Must […]

[wpdm_tree category=”vsm-templates”] VSM Process Symbols Customer/Supplier This icon represents the Supplier when in the upper left, the usual starting point for material flow. The customer […]

Can You Say PPAP? PPAP stands for Production Part Approval Process. If you want to sound cool, you will pronounce the acronym pee-pap. The term PPAP […]

Abstract. Supply strategies in a lean environment should support the operations strategy. It is appropriate then to use lean concepts and lean terminology in the […]

Focused improvement is the engine of WCM. As the one of ten World Class Manufacturing pillars, Focused Improvement have a big task to manage the […]

Copyright © 2024 | WordPress Theme by MH Themes