The 5S program highlights basic aspects such as using the proper tool, the proper accessory, and the correct information.

It seeks respect for arranged times and established order. It focuses on details that are seen in any workplace, but they do not seem very important in regards to the big problems that need to be faced on a daily basis.

However, when attention is not paid to these little basic details, even bigger problems will show up in the future. Adopting this method guarantees success, not only at work, but also in personal aspects of your life.

When the 5S program is considered, it will be seen as a very flexible program, and it includes characteristics that involve safety, order, cleanliness, elimination, etc. One of the most important points in the 5S is that of cleanliness. It is considered impossible to perform a task properly in a dirty, untidy place.

The system teaches you to work in a clean and tidy environment, where everything is in order, clean, and neat. As much as this principle is applied at work, it can also be applied at home. This philosophy teaches you to be a clean and tidy person in every aspect of life.

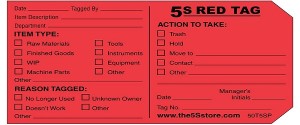

Cleanliness starts by putting things in order, eliminating, or storing useless items in the workplace.

This is a Japanese philosophy and it is necessary to understand that they are very strict in this aspect. Discarding useless items allows the possibility to have more room and makes it possible to find things easily – since only essential tools, objects, or items will be present.

On the other hand, the same philosophy can be applied at a personal level. Hence, it is fundamental to keep only the essential. Why keep things that will no longer be used at home? This is why this philosophy is regarded as eco friendly: storing and recycling is needed, in the pursuit of leaving no impact on Earth. This reflects a deep concern on the footprints individuals leave on the ecosystem.

Another factor that contributes to cleanliness is systematization.

Tasks are standardized and a routine has to be created, in order to ensure that every detail of tasks is performed. And cleanliness is part of that daily routine, when the 5S system is applied.

Japanese workers carry out a cleaning routine, irrespective of the hierarchy. Visual impact is also considered. People must show a clean and tidy appearance, wearing sanitary clothes, glasses, gloves and shoes. It is common to find many mirrors on the walls at Japanese workplaces. But why do they do this? The idea is to reflect people’s appearance in order to help them to keep clean.

Every worker has a second uniform to be used if necessary. In many industries there is even a laundry where everyone can have their uniforms cleaned up, in case they are not dirt free.

One of the key elements of these principles is to make sure that employees truly believe that this is going to make a difference in not only at work, but as an integral part of individuals’ life.

[wpdm_tree category=”5s-forms”]