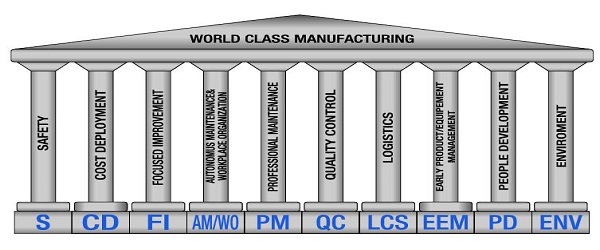

WCM foresees 10 technical pillars and 10 managerial pillars. The levels of accomplishment in technical fields are indirectly affected by the level of accomplishment in administrative fields.

The WCM pillars structure represents the “Temple of WCM” and points out that, to achieve the standard of excellence, a parallel development of all the pillars is necessary. Each pillar focuses on a specific area of the production system using appropriate tools to achieve excellence global.

Here below in Table 1.1 features for each WCM technical pillars are illustrated.

|

Technical Pillar |

Why |

Purpose |

|---|---|---|

|

SAF |

Continuous improvement of safety |

To reduce drastically the number of accidents. |

|

CD |

Analysis of the losses and costs (losses within the costs) |

To identify scientifically and systematically the main items of loss in the system production-logistics business. |

|

Priorities of actions to management the loss identified by the cost deployment |

To reduce drastically the most important losses present in the system manufacturing plant, eliminating inefficiencies. |

|

|

AA Autonomous Activities |

Continuous improvement of plant and workplace |

It is constituted by two pillars: |

|

PM Professional Maintenance |

Continuous improvement of downtime and failures |

To increase the efficiency of the machines using failure analysis techniques. |

|

QC |

Continuous improvement of customers’ needs |

To ensure quality products. |

|

LOG Logistics & Customer Service |

Optimization of stocks |

To reduce significantly the levels of stocks. |

|

EEM |

Optimization of installation time and costs and optimization of features of new products |

To put in place new plants as scheduled. |

|

PD |

Continuous improvement of the skills of employees and workers |

To ensure, through a structured system of training, correct skills and abilities for each workstation. |

|

ENV Environment ENE Energy |

Continuous improvement environmental management and reduce energy waste |

To comply with the requirements and standards of environmental management. |

As regards the ten WCM Managerial Pillars there are:

- Management Commitment;

- Clarity of Objectives;

- Route map to WCM;

- Allocation of Highly Qualified People to Model Areas;

- Organization Commitment;

- Competence of Organization towards Improvement;

- Time and Budget;

- Detail Level;

- Expansion Level and

- Motivation of Operators