How to make an 8d report

An 8D report, also known as the Eight Disciplines problem-solving methodology, is a structured approach used in the business and manufacturing sectors to identify, correct, […]

An 8D report, also known as the Eight Disciplines problem-solving methodology, is a structured approach used in the business and manufacturing sectors to identify, correct, […]

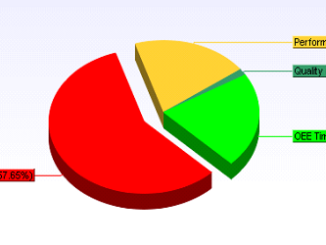

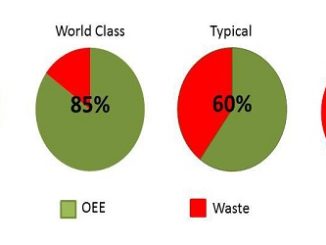

OEE Calculation example OEE is formulated as a function of a number of mutually exclusive components, such as availability efficiency, performance efficiency, and quality efficiency […]

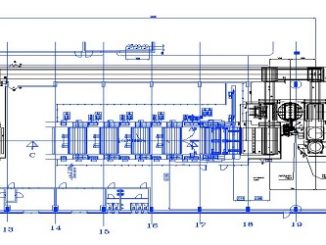

Finally, it is important to consider how the focus of the design may vary according the type of production system. In flow-shop production system the […]

The OEE of each equipment, as isolated machine (independent by other station) is affected only by (5),(6) and (7) theoretical intrinsic value. But once the […]

In this paragraph we will provide process designer with a set of topics that need to be addressed when considering the OEE during the design […]

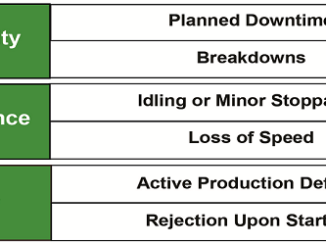

For the design of a production system several time-losses, of different nature, need to be considered. Literature is plenty of classifications in this sense, although […]

Different metrics for measuring and analyzing the productivity of manufacturing systems have been studied for several decades. The traditional metrics for measuring productivity were throughput […]

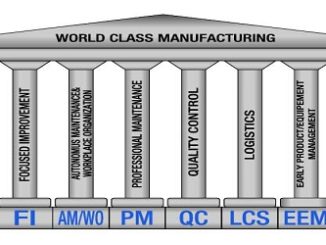

The aim of this work is to present establishments of the basic model of World Class Manufacturing (WCM) quality management for the production system at […]

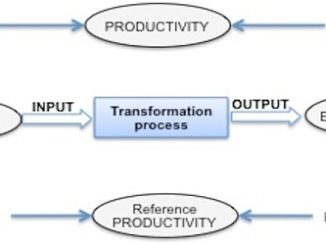

Difference between efficiency and productivity Productivity is defined as the actual output over the actual input (e.g. number of final products per employee), and both […]

“If you can not measure it, you can not improve it.”(Lord Kelvin) It is a common opinion that productivity improvement is nowadays the biggest challenge […]

Imagine you wake up one morning realising you have a sore head, the usual remedies don’t work, you think it may even be something quite […]

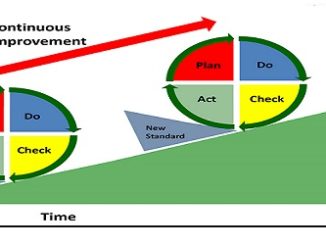

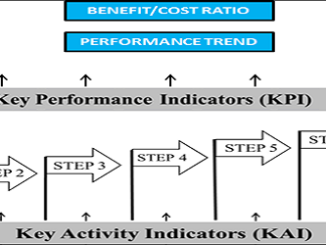

In World Class Manufacturing the focus is on continuous improvement. As organizations adopt world class manufacturing, they need new methods of performance measurement to check […]

WCM foresees 10 technical pillars and 10 managerial pillars. The levels of accomplishment in technical fields are indirectly affected by the level of accomplishment in […]

The process to achieve “World Class Manufacturing” (WCM) has a number of philosophies and elements that are common for all companies. Therefore, when applied to […]

Manufacturers in many industries face worldwide competitive pressures. These manufacturers must provide high-quality products with leading-edge performance capabilities to survive, much less prosper. The automotive […]

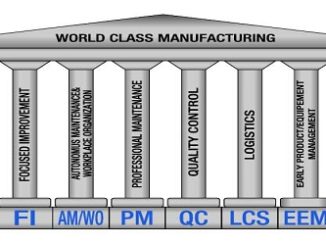

WCM requires all decisions to be made based on objective measured data and its analysis. Therefore, all the traditional data analysis tools such as scatter […]

Also Called: Cause and Effect Diagram. A fishbone diagram helps team members visually diagram a problem or condition’s root causes, allowing them to truly diagnose […]

Of the 28 main sections of ISO 9001:2015, the IATF 16949 Standard adds requirements under 22 of them. The table shows where there are additional […]

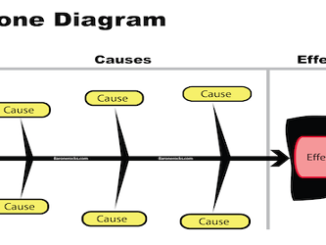

Mean Time Between Failure (MTBF) Is a reliability term used to provide the amount of failures per million hours for a product. This is the […]

Many organisations feel that the issues and problems they face are unique to themselves. Fortunately this is not true and therefore we are able to […]

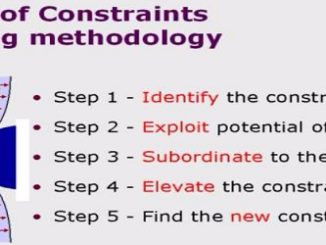

What is it? TOC is a thinking process designed to help organizations focus their effort during a continuous improvement process. The focusing methodology follows these […]

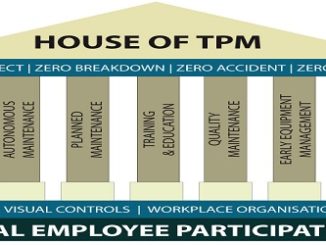

What is TPM? The focus of TPM is on equipment and people with the objective being the elimination of all forms of equipment losses. Equipment […]

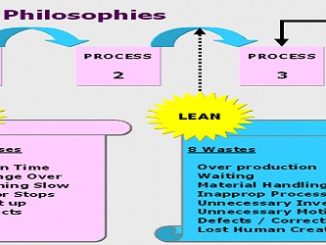

Lean Thinking is about making continuous improvements to enhance business performance. A number of Continuous Improvement philosophies and techniques have evolved. These include, Total Productive […]

However, one might ask, “where does the relationship life cycle fit with all this talk of the New Economy?” The answer to this question is […]

The Relationship Life Cycle is the next phase beyond the customer life cycle. The customer life cycle assumed that a seller should simply aggregate the […]

All companies communicate with their partners using three basic building blocks. They Exchange, Integrate and/or Collaborate Exchange is the realm of the EDI providers or […]

Step 1: Identify Comparison Opportunities Sales Forecasts Unless a manufacturer has implemented Vendor Managed Inventory, or has assumed the technology to support VMI, this can […]

In the generation of science basically there are lots of improvements are shown in the society with the help of the sciences. Science has enhanced […]

Copyright © 2024 | WordPress Theme by MH Themes